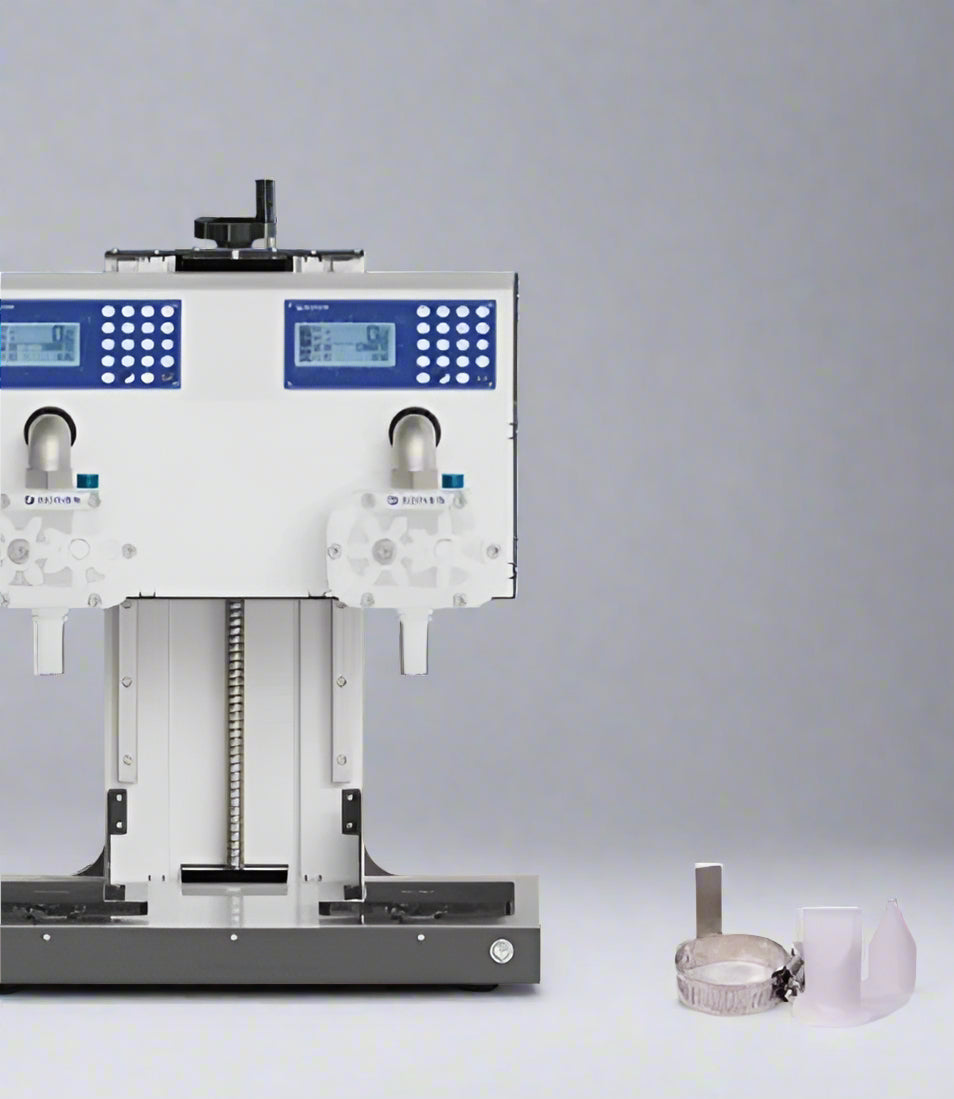

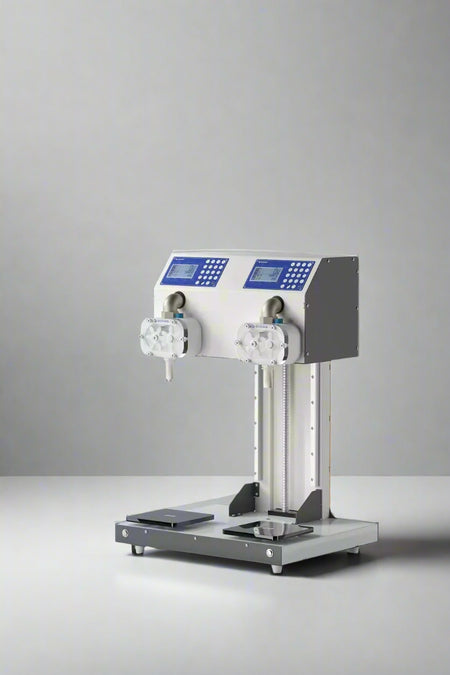

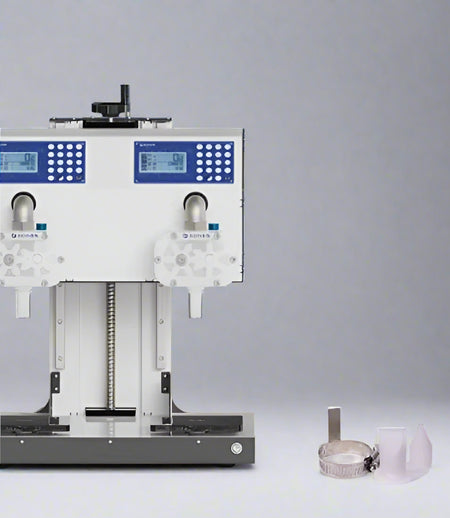

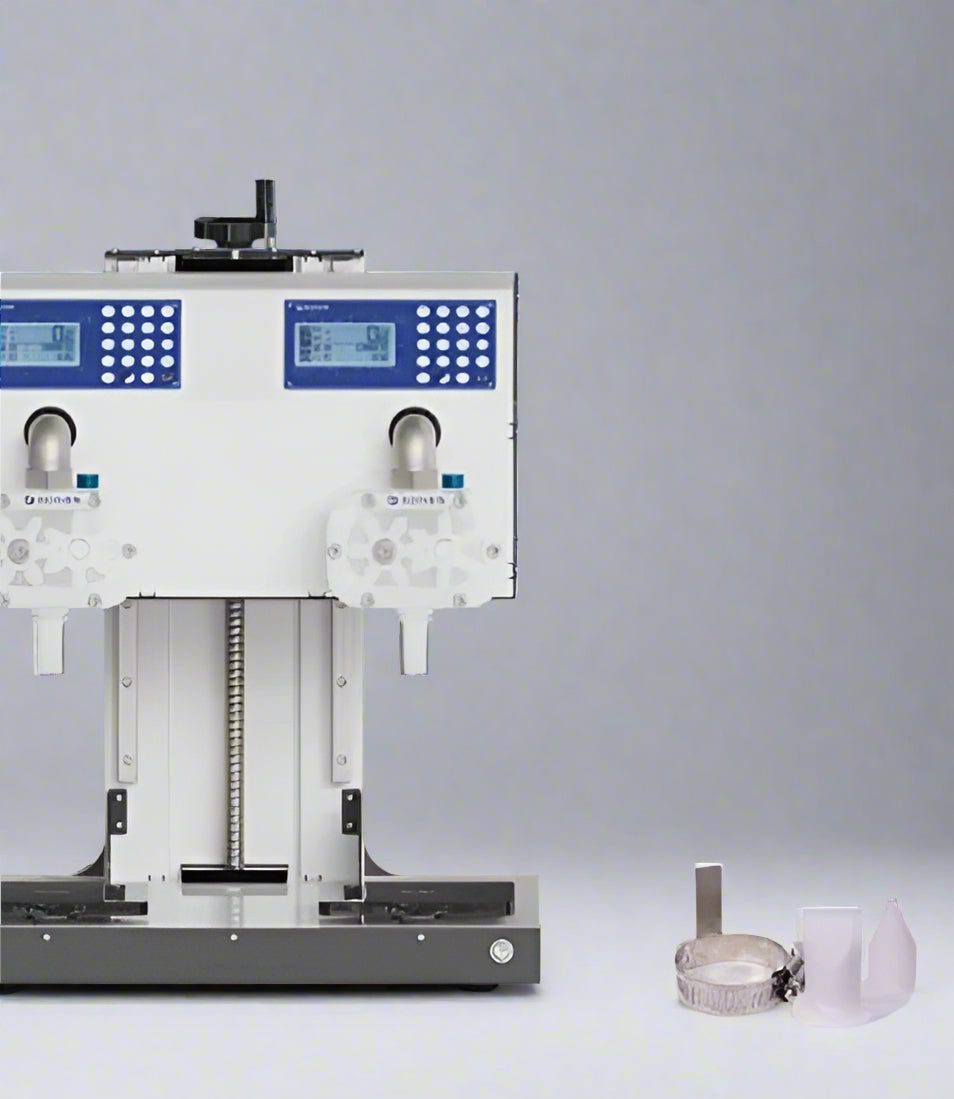

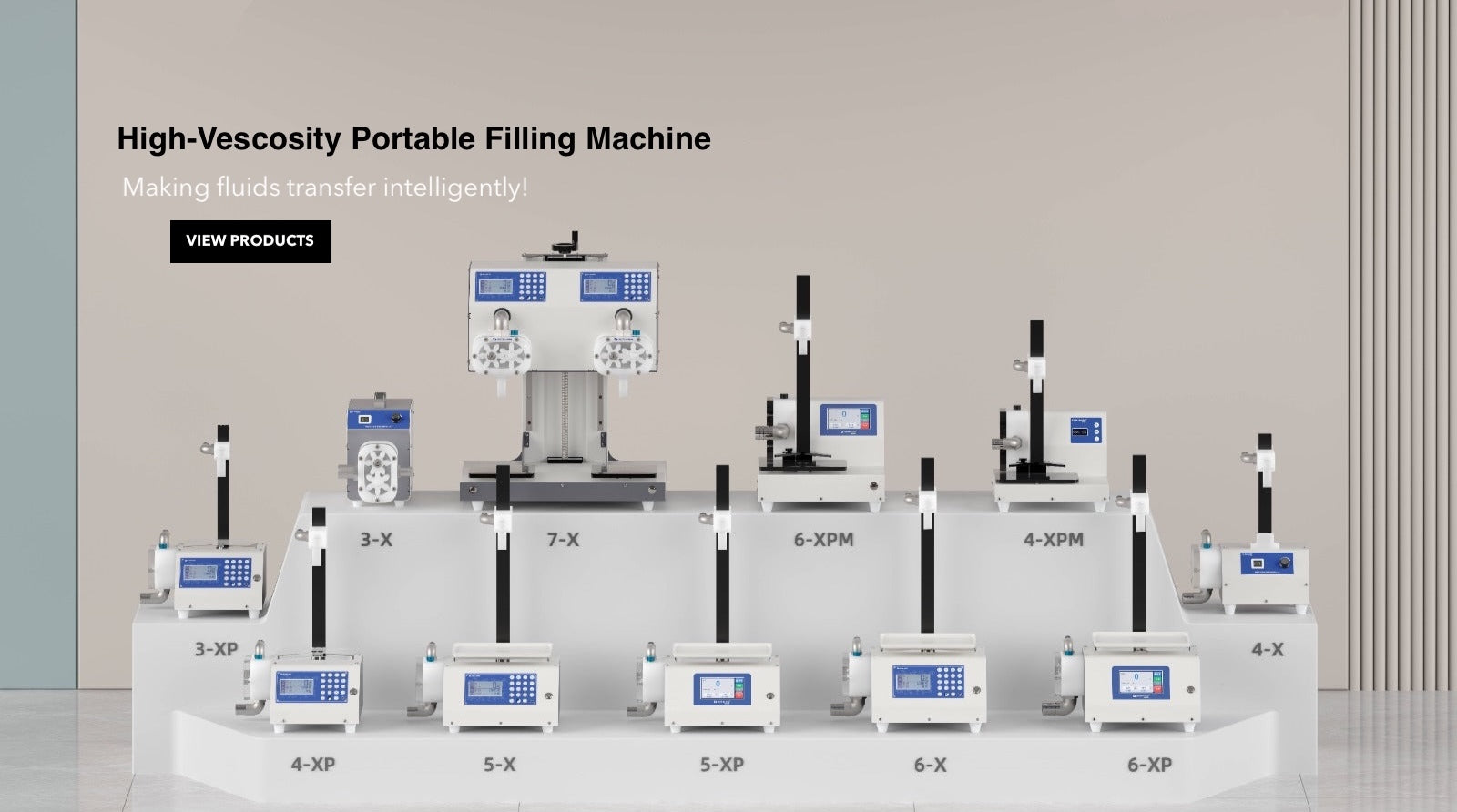

7-X Series Dual-Head High-Viscosity Filling Machine

Regular price

$3,250.00

Need a Custom Quote?

Tell us what you need — we’ll respond quickly with pricing and details.

Payment details

Help your customers identify what payments are accepted by your store.

Equipped with dual heads for high-volume, high-viscosity liquid filling. Suitable for jam, paste, and viscous sauces.

- Brix: <43.5°Bx, T >10°C

- Pump Type: Gear

| SKU | Image | Model | Brix | Rated Voltage | Rated Power | Weight | Packing | Pump Type | Flow Rate | Viscosity Capacity | Bottle Height | More Info |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 3-X-FM |  |

3-X (Conveyor) | For honey < 44°Bx | 110V-240V | ≤120w | 10kg | 310*168*245mm | Gear | 900-1000L/h | 1000CP-18000CP | / | View Details |

| 4-XP-FM |  |

4-XP | For honey < 42.5°Bx and T > 20°C | DC12V AC100-240V | ≤120w | 9KG | 400*400*250mm | Gear | 4.5L/min | 1000CP-18000CP | 20g-5000g | View Details |

| 5-X-FM |  |

5-X | For honey < 42.5°Bx and T > 20°C | DC24V AC100-240V | ≤120w | 10KG | 400*400*250mm | Gear | 6L/min | 1000CP-18000CP | 30g-6000g | View Details |

| 5-XP-FM |  |

5-XP | For honey < 43.5°Bx and T > 10°C | DC24V AC100-240V | ≤250w | 13KG | 400*400*320mm | Gear | 10L/min | 1000CP-18000CP | 30g-10000g | View Details |

| 6-XP-FM |  |

6-XP | For honey < 43.5°Bx and T > 10°C | DC24V AC100-240V | ≤250w | 13KG | 400*400*320mm | Gear | 10L/min | 1000CP-18000CP | 30g-10000g | View Details |

| 7-X-FM |  |

7-X | For honey < 43.5°Bx and T > 10°C | DC24V AC100-240V | ≤250w | 35KG | 605*495*510mm | Gear | 20L/min | 1000CP-18000CP | 50g-10000g | View Details |

| 8-X-2-FM |  |

8-X-2 | For honey < 43.5°Bx and T > 10°C | 110V-240V | ≤260w | 25KG | 580*420*400mm | Gear | 11L/min | 1000cp-18000cp | 10g-10000g | View Details |

| 8-X-1-FM |  |

8-X-1 | For honey < 43.5°Bx and T > 10°C | 110V-240V | ≤260w | 25KG | 580*420*400mm | Gear | 11L/min | 1000cp-18000cp | 10g-10000g | View Details |

| 9-X-2-FM |  |

9-X-2 | For honey < 42.5°Bx and T > 10°C | 110V-240V | ≤260w | 20KG | 500*350*350mm | Gear, Impeller, Peristaltic | 15L/min | 50cp-10000cp | ≥1g | View Details |

| 9-X-1-FM |  |

9-X-1 | For honey < 42.5°Bx and T > 10°C | 110V-240V | ≤260w | 20KG | 500*350*350mm | Gear, Impeller, Peristaltic | 15L/min | 50cp-10000cp | ≥1g | View Details |

| 2-X-FM |  |

2-X | For honey < 43.5°Bx and T > 20°C | 110V-240V | ≤260w | 16KG | 405*380*585mm | Gear | 11L/min | 1000cp-18000cp | ≥10g adjustable | View Details |

| 13-Y-FM |  |

13-Y | 316L pump, can be used for corrosive liquids | 110V-240V | ≤120w | 8KG | 320*260*555mm | Magnetic Gear | 6L/min | 1-100CP | 10g-10000g | View Details |

| 5-Y-FM |  |

5-Y | Suitable for liquids containing particles ≤ 6mm | 110V-240V | ≤120w | 9KG | 340*260*555mm | Flexible Impeller Pump | 15L/min | / | 100g-10000g | View Details |

| 8-X-3-FM |  |

8-X-3 | For honey < 43.5°Bx and T > 10°C | 110V-240V | ≤400w | 65KG | 885*670*635mm | Gear | 10L/min | 1000-18000CP | 5g-2000g | View Details |

| 9-X-4-FM |  |

9-X-4 | For honey < 42.5°Bx and T > 10°C | 110V-240V | ≤400w | 62KG | 850*600*635mm | Gear | 10L/min | 1000-18000CP | 1g-500g | View Details |

| L-1-FM |  |

L-1 | 316L (material) | / | / | / | / | / | / | / | / | View Details |

| L-2-FM |  |

L-2 | 316L (material) | / | / | / | / | / | / | / | / | View Details |

| L-3-FM |  |

L-3 | 316L (material) | / | / | / | / | / | / | / | / | View Details |

| L-4-FM |  |

L-4 | 316L (material) | / | / | / | / | / | / | / | / | View Details |

| L-5-FM |  |

L-5 | 316L (material) | / | / | / | / | / | / | / | / | View Details |

| L-6-FM |  |

L-6 | 316L (material) | / | / | / | / | / | / | / | / | View Details |

| L-7-FM |  |

L-7 | 316L (material) | / | / | / | / | / | / | / | / | View Details |

| L-8-FM |  |

L-8 | / | / | / | / | / | / | / | / | / | View Details |

| L-9-FM |  |

L-9 | / | / | / | / | / | / | / | / | / | View Details |

| L-10-FM |  |

L-10 | / | / | / | / | / | / | / | / | / | View Details |

| L-11-FM |  |

L-11 | / | / | / | / | / | / | / | / | / | View Details |

Smart Liquid Filling Machine

Automatically adjusts filling parameters, reducing human error and increasing efficiency. Delivers consistent ad precise filling for enhanced product quality. Enhance your production process with the automated filling system, designed to minimize errors and boost productivity. Experience reliable and accurate filling for top-quality products.